For a few years now, I’ve been thinking about the idea of jewellery that was made from

industrial materials instead of precious metals and flawless, cut gemstones. I wondered what it

would be like to see a rough, industrial diamond set in an iron or steel ring. From a cost perspective,

you could have a diamond many times larger than what the average person would be able to afford if it

were a jewellery grade stone. With our upcoming wedding in June, I offered to make a ring for my fiancee

but she didn’t fancy the idea of a rusty, jagged piece of industrial metalwork so I settled for

making one for myself.

After doing some research on different metals, I decided to go with a ring made from 316L stainless

steel and C145 tellurium copper. This steel alloy is commonly used in jewellery due to its corrosion

resistance and I chose C145 copper because of its machinability.

The design will be a simple steel band with seven copper inserts evenly spaced around the

circumference.

Centering stock on rotary table with dial indicator

My mini lathe is too feeble to drill a big enough hole for the boring bar...

...So I made several plunges with an endmill while rotating the table in between plunges

Rotary table mounted on its side

Seven 0.125" holes were drilled around the circumference

Next to it is an aluminum test ring I made to get the right size for my finger

Turning the tip of the copper plugs to a sliding fit

...but the rest is 0.001" bigger for a "hammer" fit

Test fitting one of the plugs

Plugs are then hammered in place

Five plugs in place

Seven plugs in place

A carbide Dremel bit is used to remove the excess copper

...From the inside...

...And the outside

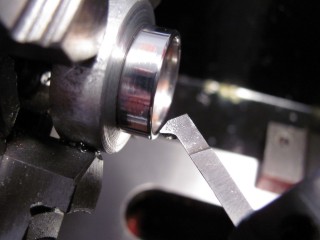

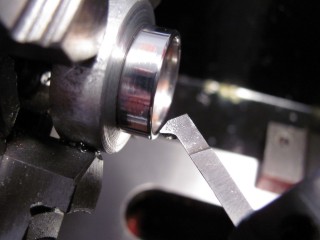

The rest of the copper can now be removed with the lathe

After cleaning up, but before chamfering

After parting off the ring, I noticed a problem...

The copper plugs were not centered within the band

Measuring the offset with calipers wouldn’t be very accurate

So I scanned the ring with a flatbed scanner and counted pixels

Then I made a mandrel to hold the ring in the lathe again

I then turned one side down a bit and re-chamfered the edges

Finally, I polished it with Brasso and a Dremel with a felt tip

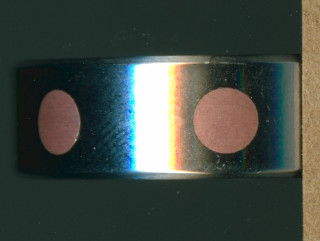

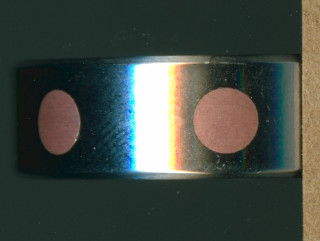

The finished ring

Finished ring, second view

Finished ring, installed.